Dynamic Engineering Manufacturing

People, Processes, Equipment

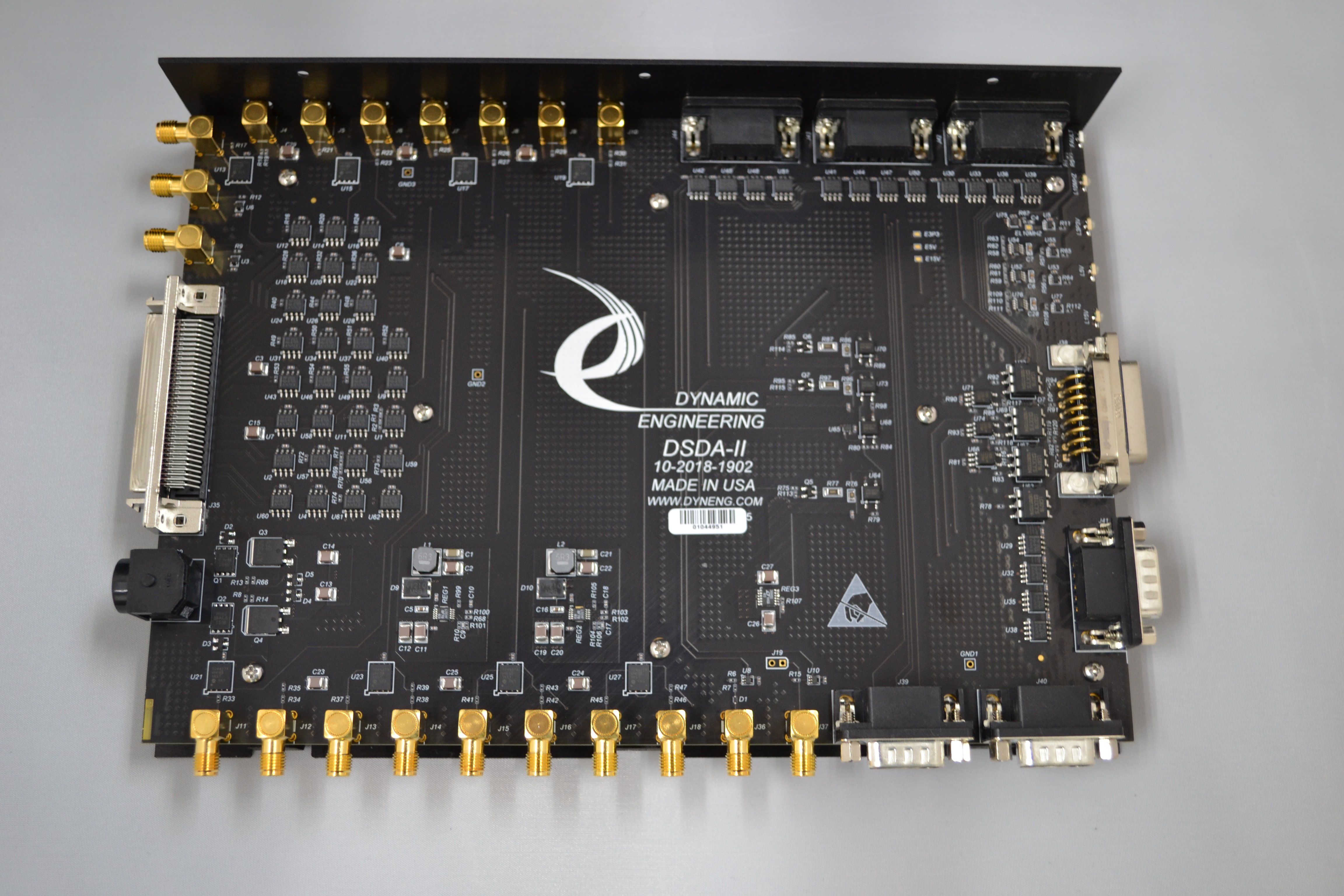

Dynamic Engineering is an AS9100 certified company with full process control. Customized ERP system in use to support full traceability for components and finished products.

Dynamic Engineering has an IPC-A-610 Certified Trainer on-staff who ensures that all product quality requirements are met during manufacturing and QA processes, and all manufacturing staff are appropriately trained to utilize the IPC Specification.

Dynamic Engineering products are designed, manufactured, and tested in the USA. Most assembly work is done in our state-of-the-art manufacturing facility in Santa Cruz, CA. Manufacturing is a constantly evolving process.

Since 1988 we have developed and continue to improve purchasing, manufacturing, and test capabilities to guarantee reliability in our products.

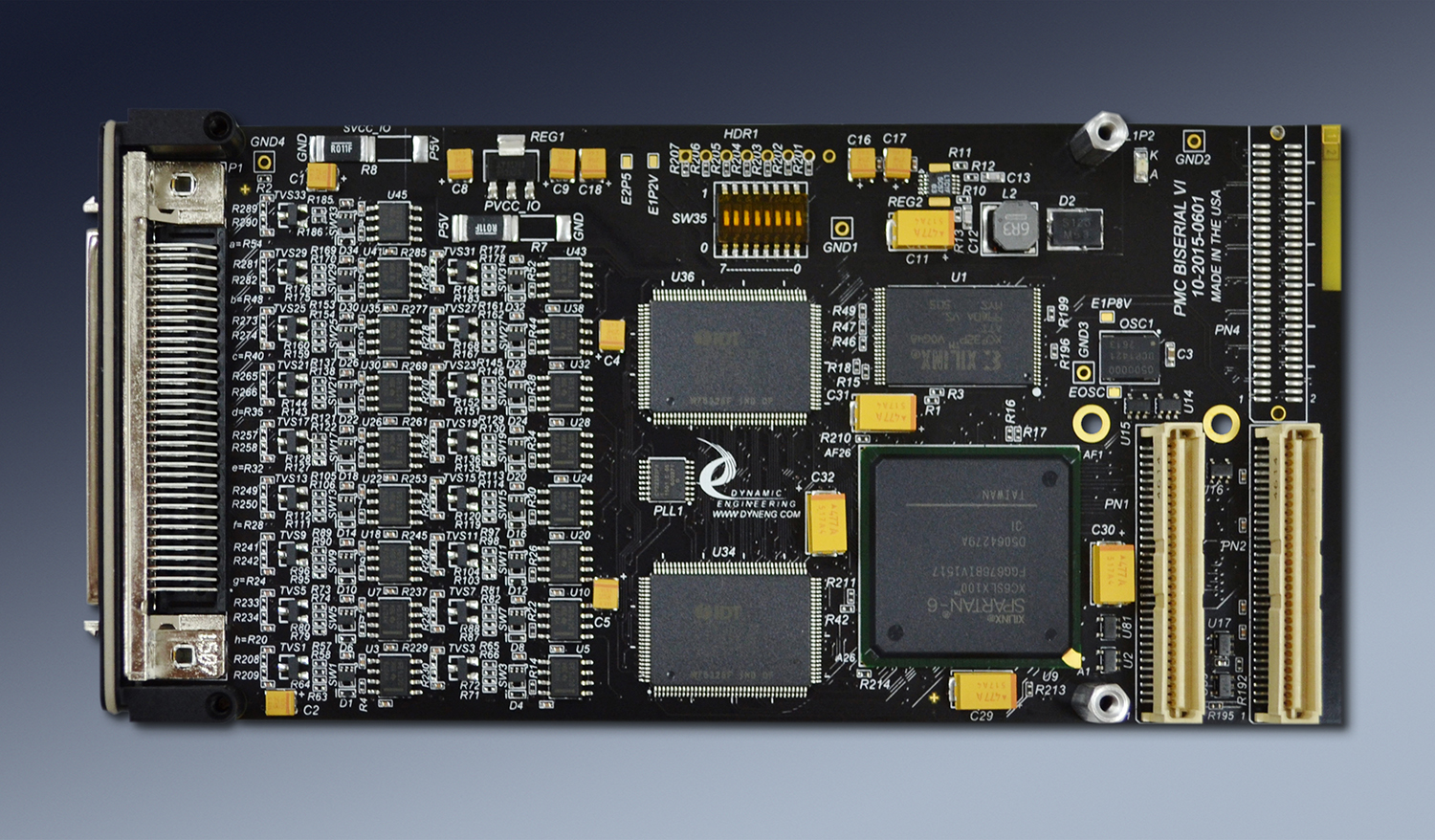

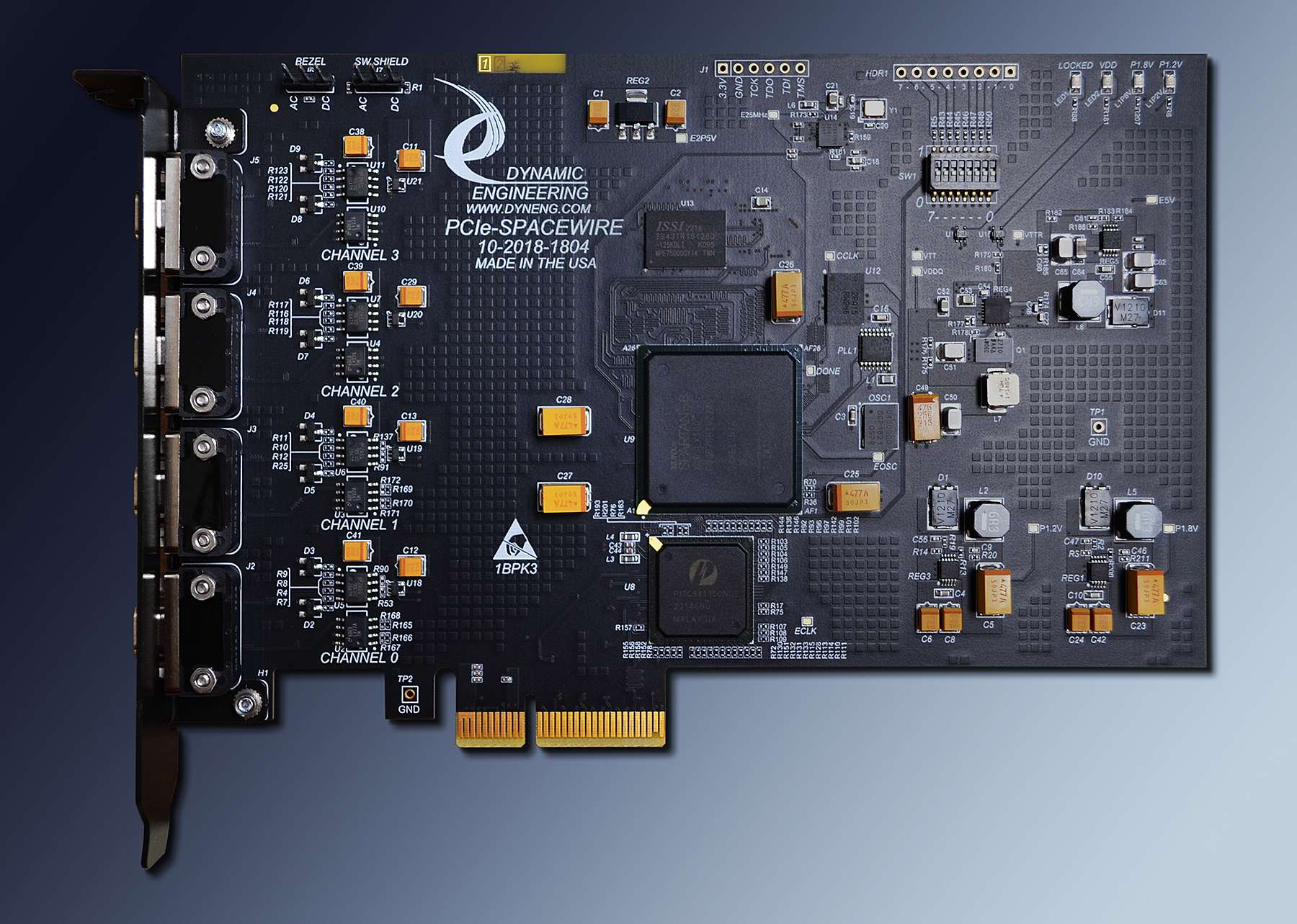

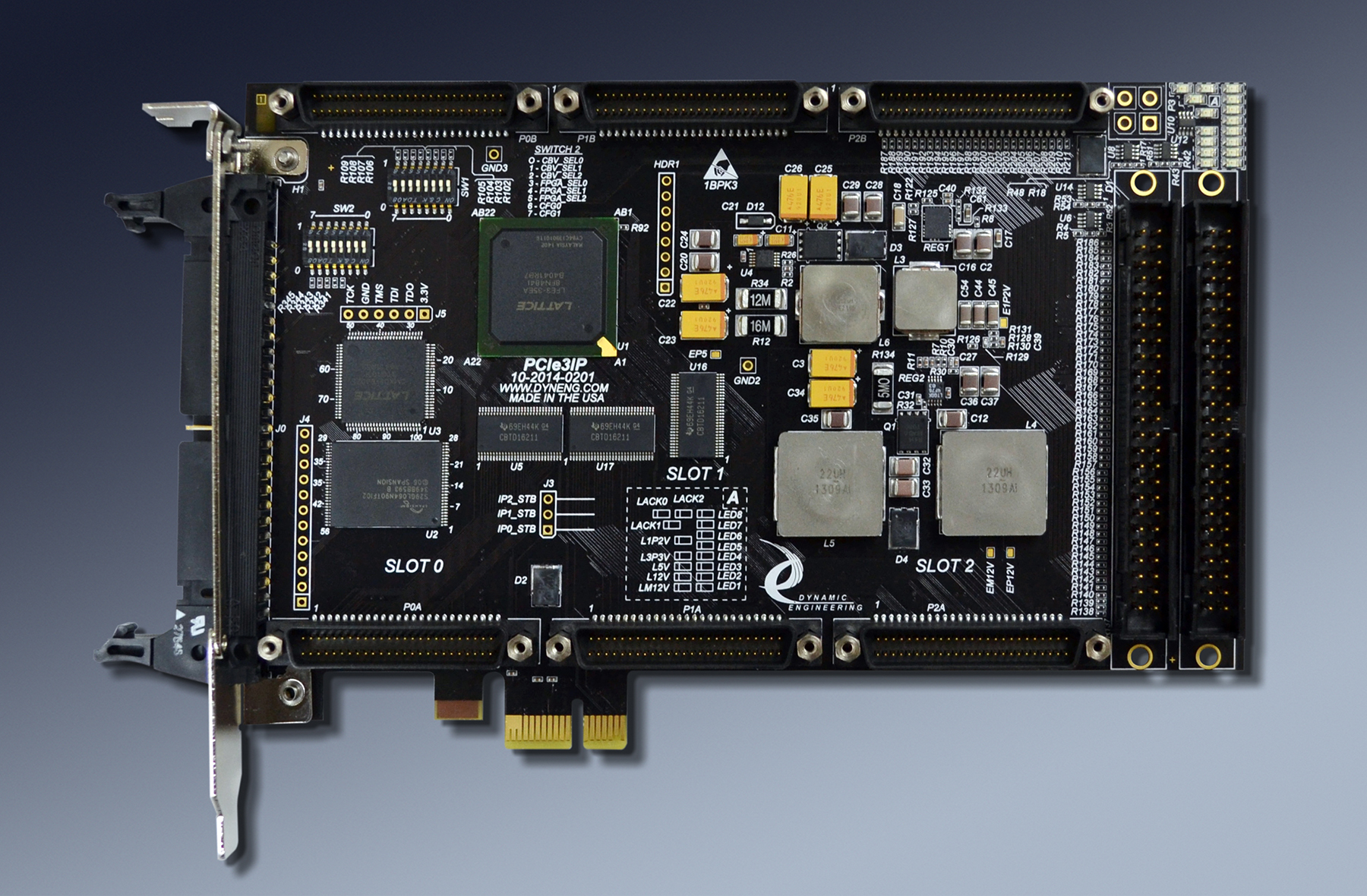

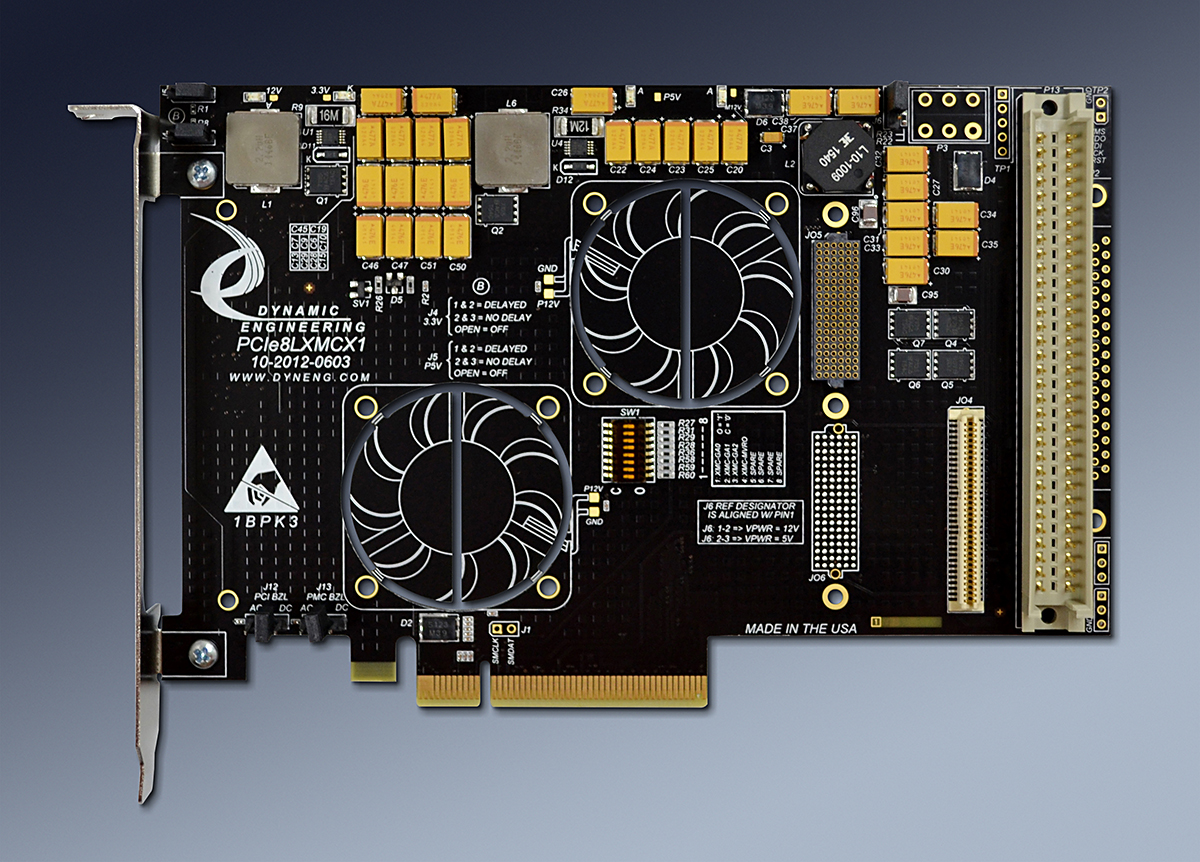

Dynamic Engineering Assemblers are qualified to work with surface mount, and through hole devices. Our assemblers assist engineering with prototyping and developmental cuts & jumpers while providing valuable feedback to help with the finished product. The Dynamic Engineering production team can handle small and large quantity builds with ROHS or standard soldering techniques.

We have the right tools for the job with automatic stencil printer, multi-head Pick and Place, 7 zone IR reflow oven with nitrogen, automated board wash with filtered water system [DI], C-3 cleanliness testing, X-RAY, AOI, temperature chamber, hand assembly rework tools, production test fixtures and customized software.

Dynamic Engineering manufactures equipment and cables to support the use of your pre-existing equipment as well as the products we supply. We offer cables for SpaceWire, breakouts for SCSI, Ribbon, VHDCI, and D100 as well as special purpose breakouts for 1553, UART, and other interfaces; additionally, we design and build custom cables and solutions to support different software and hardware use. We use a state-of-the-art Hipot and in some cases real-time signal testing to ensure cables function as designed.

Special documentation is available for projects with more stringent requirements. Production reports including cleanliness, test, BOM, PCB incoming, process flow chart, control plan, PFME, yield, photos. XRAY and AOI reports are also available.

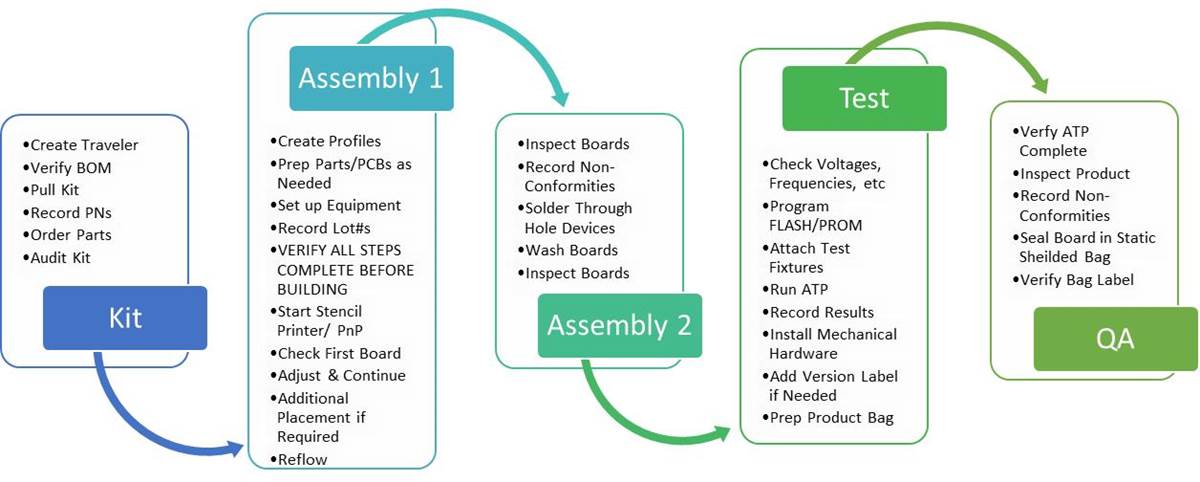

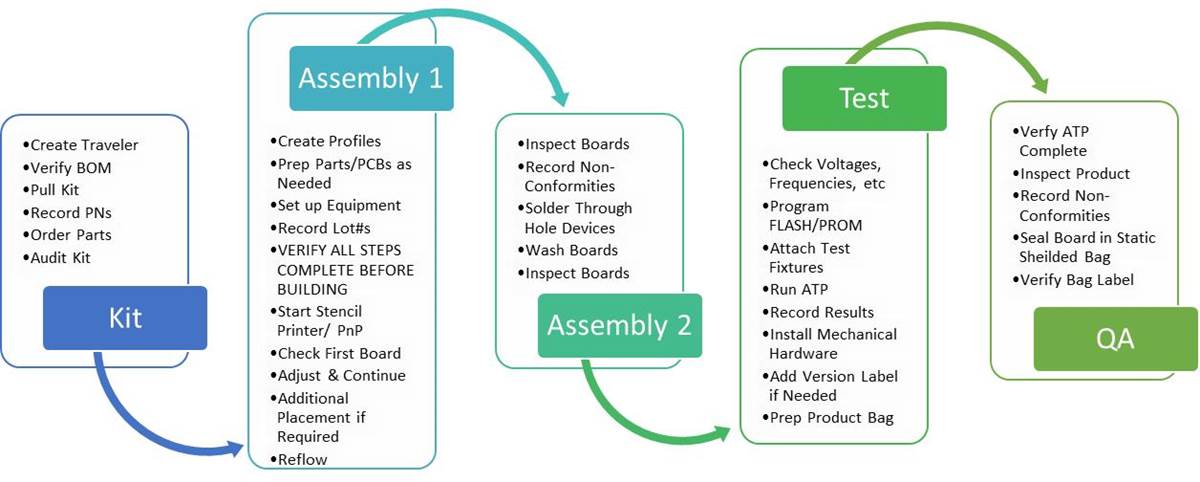

Dynamic Engineering PCB products use the above work flow to make their way through manufacturing.

High quality parts, people and processes lead to high quality products.

Our Engineering staff will design your product to meet your requirements and allow for testability and manufacturability. Overall product cost is reduced with proper planning and systems.

Dynamic Engineering´s responsiveness is outstanding largely due to co-located Design, Development, Purchasing, Production, and Test departments.

Dynamic Engineering constantly looks for ways to reduce our carbon footprint and go green including the use of solar panels (133 panels / 3 phase/ 43 KW AC) and energy-efficient equipment where possible. We also reduce, reuse, and recycle wherever practical.

Dynamic Engineering has an IPC-A-610 Certified Trainer on-staff who ensures that all product quality requirements are met during manufacturing and QA processes, and all manufacturing staff are appropriately trained to utilize the IPC Specification.

Dynamic Engineering products are designed, manufactured, and tested in the USA. Most assembly work is done in our state-of-the-art manufacturing facility in Santa Cruz, CA. Manufacturing is a constantly evolving process.

Since 1988 we have developed and continue to improve purchasing, manufacturing, and test capabilities to guarantee reliability in our products.

Dynamic Engineering Assemblers are qualified to work with surface mount, and through hole devices. Our assemblers assist engineering with prototyping and developmental cuts & jumpers while providing valuable feedback to help with the finished product. The Dynamic Engineering production team can handle small and large quantity builds with ROHS or standard soldering techniques.

We have the right tools for the job with automatic stencil printer, multi-head Pick and Place, 7 zone IR reflow oven with nitrogen, automated board wash with filtered water system [DI], C-3 cleanliness testing, X-RAY, AOI, temperature chamber, hand assembly rework tools, production test fixtures and customized software.

Dynamic Engineering manufactures equipment and cables to support the use of your pre-existing equipment as well as the products we supply. We offer cables for SpaceWire, breakouts for SCSI, Ribbon, VHDCI, and D100 as well as special purpose breakouts for 1553, UART, and other interfaces; additionally, we design and build custom cables and solutions to support different software and hardware use. We use a state-of-the-art Hipot and in some cases real-time signal testing to ensure cables function as designed.

Special documentation is available for projects with more stringent requirements. Production reports including cleanliness, test, BOM, PCB incoming, process flow chart, control plan, PFME, yield, photos. XRAY and AOI reports are also available.

Dynamic Engineering PCB products use the above work flow to make their way through manufacturing.

High quality parts, people and processes lead to high quality products.

Our Engineering staff will design your product to meet your requirements and allow for testability and manufacturability. Overall product cost is reduced with proper planning and systems.

Dynamic Engineering´s responsiveness is outstanding largely due to co-located Design, Development, Purchasing, Production, and Test departments.

Dynamic Engineering constantly looks for ways to reduce our carbon footprint and go green including the use of solar panels (133 panels / 3 phase/ 43 KW AC) and energy-efficient equipment where possible. We also reduce, reuse, and recycle wherever practical.

Manufacturing Features

- Complete Traceability

- All components and boards are only handled at ESD safe workstations, and all manufacturing personnel are required to wear ESD protective clothing and wrist straps

- Speedline MPM Accuflex Stencil Printer

- Panasonic AM100 Pick and Place

- Vitronics Soltec XMP3 IR Reflow oven

- OnSite Nitrogen Separator

- Aqueous Tech. SMT PCB Cleaning System "Trident LDO"

- 100% Full Function Testing of ALL Products

- Custom Drivers and Test Software

- Temperature Chamber and Burn-in available

- Every Product Inspected

- Mirtec MV-3omni AOI

- Nikon XT V 130C X-RAY

- CAMI Research CableEye Hipot

- ROHS or Leaded Processes

- Conformal Coating

- Custom Rework

- Custom Builds

- Special Reports

| AS9100 Certified ESD Safe |

|

| |

|

| Automated SMT Assembly Line |

|

| |

|

| Test & QA | |

| |

|

| Options | |

| |

cPCI-6U-COOL Manuals

No Manual required for this product. Please send any questions to sales@dyneng.com for a prompt answer.